Titanium Alloy Grade 5/Ti6Al4V Manufacturer, Suppliers, Factories and Company - SHAANXI SHEW-E IRON & STEEL CO., LTD

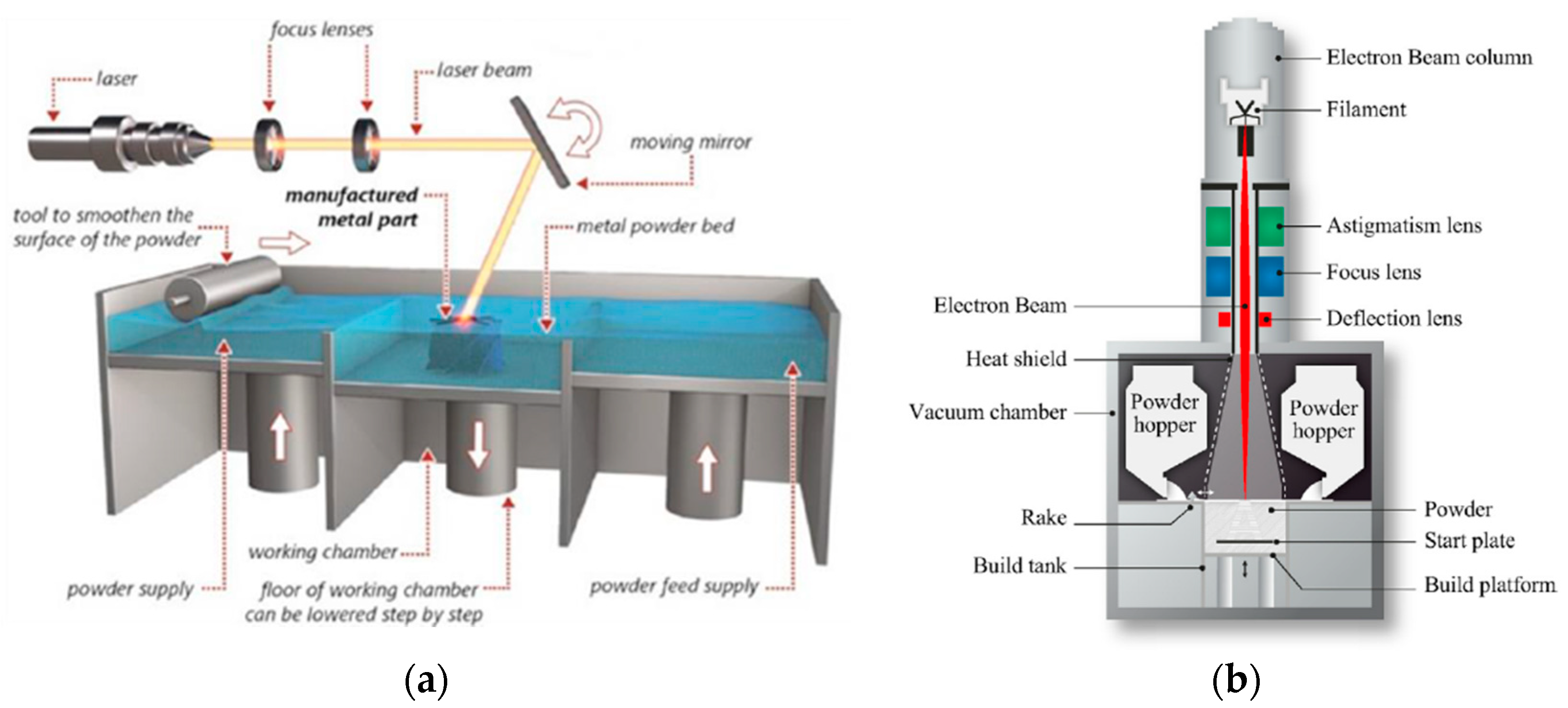

On the anisotropy in room-temperature mechanical properties of laser powder bed fusion processed Ti6Al4V-ELI alloy for aerospace applications | SpringerLink

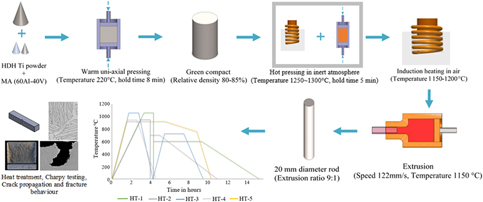

The effect of heat treatment on the mechanical properties of Ti–6Al–4V alloy produced by consolidating a high impurity blended powder mixture using a combination of powder compact hot pressing and extrusion

The effect of heat treatment on the mechanical properties of Ti–6Al–4V alloy produced by consolidating a high impurity blended powder mixture using a combination of powder compact hot pressing and extrusion

![Physical properties of the AA7075 alloy [MatWeb-Material Property Data] | Download Scientific Diagram Physical properties of the AA7075 alloy [MatWeb-Material Property Data] | Download Scientific Diagram](https://www.researchgate.net/publication/341391787/figure/tbl1/AS:891302480707593@1589514479256/Physical-properties-of-the-AA7075-alloy-MatWeb-Material-Property-Data.png)

Physical properties of the AA7075 alloy [MatWeb-Material Property Data] | Download Scientific Diagram

Characterization of a functionally graded material of Ti-6Al-4V to 304L stainless steel with an intermediate V section - ScienceDirect

PDF) Accepted Manuscript Investigation of Ti-6Al-4V alloy Acoustic Softening | mohammadali nasiroleslami - Academia.edu

Physical properties of Ti-6Al-4V are incorrect in Autodesk Material Library 2013 - Autodesk Community - Inventor

PDF) On different FE-based models to simulate cutting operation of Titanium alloy (Ti-6Al-4V) | Domenico Umbrello - Academia.edu